Despite numerous advantages, such as true black, energy efficiency, low response time and low thickness, OLED panels have a number of important drawbacks, the main of which is pixel burn-in. It seems that LG has managed to solve this problem.

OLED screens can burn out when displaying a static image for a long time. Most often, these are the logos of TV channels and elements of the interface of games or operating systems. The blue sub-pixel and the way it emits light compared to its red or green counterparts are to blame. The fact is that the latter emit it through phosphorescence – this method is more effective and contributes to a slower degradation of pixels. Blue subpixels require more energy to achieve the same brightness as red and green subpixels, so they use less efficient fluorescence, which shortens their lifespan.

The OLED (Organic Light Emitting Diode) panel is famous for its high-fidelity image quality, infinite contrast, and quick response time. However, the OLED panel isn’t free from flaws and cannot compete with regular LCDs when it comes to brightness. Of course, there are more problems like image burn-in, but the low brightness is one of the most common issues, which even the best quality OLED panels suffer from.

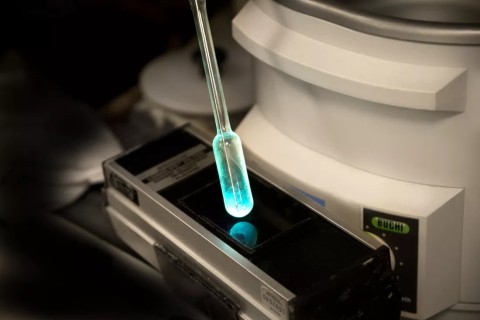

It looks like LG has found the solution to solve this problem. As reported by ETNews, LG has solved this problem through the ‘Two-Stack Tandem’ structure that helps the OLED panel achieve higher brightness & efficiency than usual. This is achieved via a hybrid structure of ‘phosphorescent’ and ‘fluorescent’ materials for the Blue OLED, which solves the root cause of the common brightness and low-efficiency issue of the OLED panel.

An OLED panel is made up of organic materials that help each pixel produce its light. There are Red, Green, and Blue OLEDs for reproducing the respective colors. While the red and green OLEDs are easier to produce using phosphorescent materials, the blue OLED faces this challenge due to its shorter wavelength. This forces the manufacturers to use fluorescent, which is typically four times less power-efficient than the phosphorescent. Not only does this introduce higher power consumption but less brightness.

As phosphorescent is approximately 100% power-efficient, the red and green OLEDs can turn 100% of the power into light while the fluorescent converts just 25% of total power to light. This not only produces dimmer light but also consumes more energy and results in faster degradation. Through the two-stack tandem structure, LG has built a blue OLED with both phosphorescent and fluorescent materials to achieve a life equivalent to conventional OLEDs while increasing the brightness and efficiency significantly.

The two-stack tandem was developed by LG in 2019 for the automotive market initially but now it has been successfully implemented for OLED display to solve the ‘last puzzle of OLED’, which an industry official called ‘a key role’ in making OLEDs more power-efficient and brighter. It’s expected that this change will increase the battery life of mobile devices with OLED displays by 10-20% and this can also be a better solution than using the quantum dot layers, which do not solve the efficiency and reliability issues.

Televisions with organic light-emitting diodes are revolutionizing the home entertainment landscape. And although scientists and electrical engineers have been working with this technology for quite some time, consumers are largely unfamiliar with it. As with any new technology, we understand that you probably have questions about OLED TVs’ reliability, performance, longevity and more. Here, you’ll find the information you need to help you better understand the technology and choose the right television for your home, your family, and the way you watch.

LG’s Dream OLED technology solves the above problem by adopting a two-layer structure with light-emitting elements stacked on top of each other. As a result, both fluorescent and phosphorescent materials are used for the blue subpixels. The company notes that this increases display efficiency by 10-20%, reducing the load on pixels.

The new technology is expected to be ready for mass production of displays within the coming year.