Taiwanese company V-Color has introduced the world’s first DDR5 RAM of the latest CUDIMM standard. It is declared to have the highest speed, as well as the ability to dynamically change the frequency and operating voltage depending on the load, which should have a positive effect on energy efficiency.

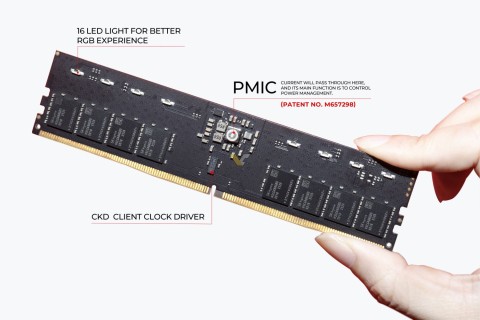

The CUDIMM (Clocked Unbuffered Dual In-Line Memory Module) standard was officially approved by the JEDEC committee in January of this year. Its advantage was the introduction of a CKD (Client Clock Driver) clock generator, which should have a positive effect on the stability of memory and its overclocking capabilities.

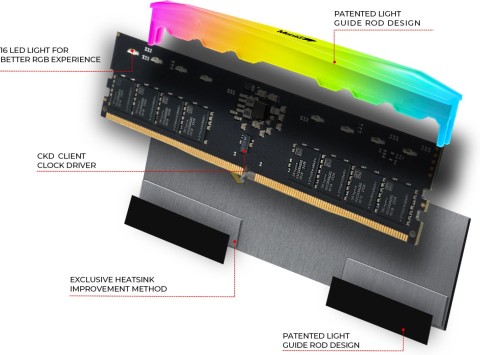

According to V-Color, the new memory is capable of operating at speeds up to 9200 MT/s with timings of 44-56-56-134 at a voltage of 1.45 V. The manufacturer also used a patented heatsink design to better dissipate heat from the modules.

V-Color has formally introduced its first CUDIMM memory modules with RGB LEDs aimed at enthusiasts. The company’s Xfinity RGB DDR5 CUDIMMs (Clock-Unbuffered Dual In-line Memory Modules) are aimed at next-generation desktop platforms and will offer data transfer rates of up to 9200 MT/s. Before we jump to what CUDIMM is, let us take a look what these modules promise.

V-Color’s CUDIMM lineup

V-Color’s RGB O CUDIMM modules will be available in 32GB (2×16GB) and 48GB (2×24GB) dual-channel kits with speed bins starting at 6400 MT/s and rising all the way to 9200 MT/s and higher, according to the manufacturer. They’re targeting Intel’s codenamed Arrow Lake platforms, and the Xfinity RGB O CUDIMMs will feature an SPD with XMP profiles for easy setup.

The modules will come equipped with heat spreaders to ensure proper cooling of memory chips, power management IC, and of course the clock driver (CKD), they key ingredient of CUDIMMs. V-Color says that its Xfinity RGB O CUDIMMs introduce an all-new patented heatsink design that’s custom-molded to adhere to memory chips more precisely, thus improving heat dissipation. As the name implies, there will also be bling, with the CUDIMMs featuring 16 RGB LEDs.

The new heatsink incorporates two 0.8 mm thick cuboids within the mold, allowing it to adhere more closely to the chips. Instead of traditional thermal tape, V-Color uses a high-performance 0.2 mm heat dissipation patch with a conductivity of 2.5 W/mK, which compresses to 0.1 mm during assembly.

The CKD also plays a crucial role in reducing clock skew, the variation in the clock signal’s arrival time across different components. By equalizing propagation delays along different clock paths, it ensures synchronized operation and precise data transfers.

Furthermore, the CKD’s ability to adjust the clock signal’s phase enables it to meet the specific timing needs of various components. That may require additional work from memory module manufacturers, but it ensures stable performance at high data transfer rates.

When will V-Color’s CUDIMMs arrive, and how much will they cost?

V-Color, like other memory module manufacturers that demonstrated CUDIMMs at Computex this year, did not disclose when they are set to start volume production of these next-generation modules. For now, it looks like CUDIMMs are positioned primarily for Intel’s upcoming Arrow Lake processors, so we expect them to hit the market later this year.

By contrast, the company’s original flat heatsinks with 3M thermal tape had a thermal connectivity of 0.9W/mK, which could result in temperatures of 86°C. The new heatsink lowers temperature by 2% – 5%, the manufacturer says.

What is CUDIMM?

A major challenge for high-performance memory subsystems is maintaining signal integrity across longer distances and multiple connections. A clock driver chip (CKD) addresses this by managing the distribution and quality of clock signals, enhancing performance and stability of DDR5 memory at high data transfer rates.

The CKD receives a base clock signal and distributes it to various memory components on the module. To preserve signal integrity, the CKD buffers and amplifies the clock signal (essentially regenerating it), ensuring it reaches all components without loss of strength. It also includes features like duty cycle correction for precise timing and jitter reduction to minimize fluctuations in the clock signal’s timing.

How much will these modules cost is the other important question. CUDIMMs are essentially simplified registered DIMMs that do not buffer the command and address busses, so they are by definition cheaper than RDIMMs. Also, a CKD chip is uses just 35 pins, which means that its integration is not too costly. Still, they will be more expensive than traditional unbuffered DIMMs. However, as it gets harder to push regular UDIMMs to higher data transfer rates, CUDIMMs will likely become default choice for ultra-high-performance memory subsystems.