Employees of Nanyang Technological University in Singapore have developed an innovative technology for the accelerated assembly of “cyborgs” based on cockroaches. The system automates the process of attaching electronic components to the bodies of insects, turning them into miniature biorobots. Researchers have taken the concept of cyborg insects to the next level – automated mass production that could turn out cybernetically controlled bugs every 68 seconds, a technology that may prove useful in search-and-rescue operations or factory inspections.

Previous experiments have found that it is possible to merge electronics with live insects to remotely control their behaviour without hurting them.

The findings, which have not been peer-reviewed, were published on the preprint platform arXiv on November 20 by Professor Hirotaka Sato with Nanyang Technological University and first author Lin Qifeng, from China.

Previously, to control the movement of cockroaches, scientists attached miniature wirelessly controlled devices to their bodies. Electrical impulses stimulated certain muscles of the insect, allowing them to set the direction of its movement. But assembling such systems by hand required high accuracy and took about half an hour.

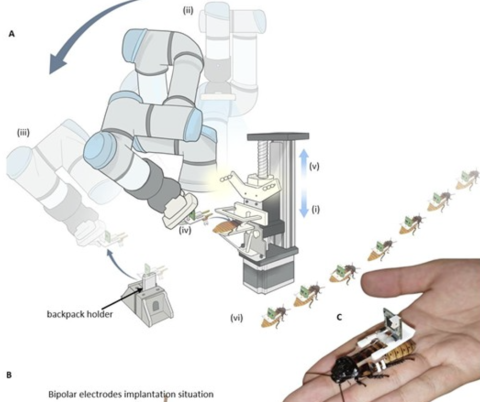

The new technology uses a robotic arm that performs the entire installation process in a matter of seconds – now it takes only 68 seconds to prepare one cyborg cockroach. Automation not only speeds up production but also scales up the assembly of hybrid robots for their mass use in real-world situations.

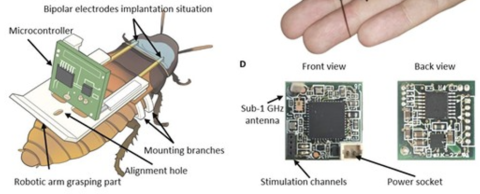

To immerse insects in a stationary state, scientists use carbon dioxide, after which they are placed on a special platform with metal holders. The structures neatly fix the insect in the desired position for the installation of chips and other components. The computer determines the ideal points for attaching the electronics, and the robotic arm performs the installation quickly and with high accuracy.

Such cyborg insects can be an effective tool in rescue operations, environmental surveillance, and the exploration of hard-to-reach places. Due to their small size, they will be able to penetrate areas where it is impossible for a person to get and transmit the collected data. In the near future, the authors plan to create a technology that allows coordinating the actions of a large number of such “cyborgs”.

The mass team previously experimented with implanting electrodes in insects to control their muscles, neural systems and sensory organs. However, manual implantation proved to be a slow and intricate process due to the delicate body structures of the insects.

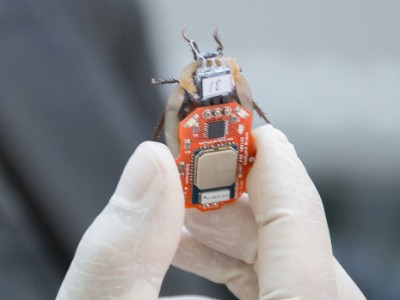

In their latest experiments, the team deployed a robot with visual capabilities to implant electronics on a cockroach, selected for its sturdy pronotum, the hard plate covering its back. The assembly process integrated a deep learning-based vision system to accurately identify implantation sites and included a specialized structure to secure the insect.

The system began with anaesthetizing Madagascar hissing cockroaches using carbon dioxide. They were then placed on a platform where metal rods automatically fixed their position.

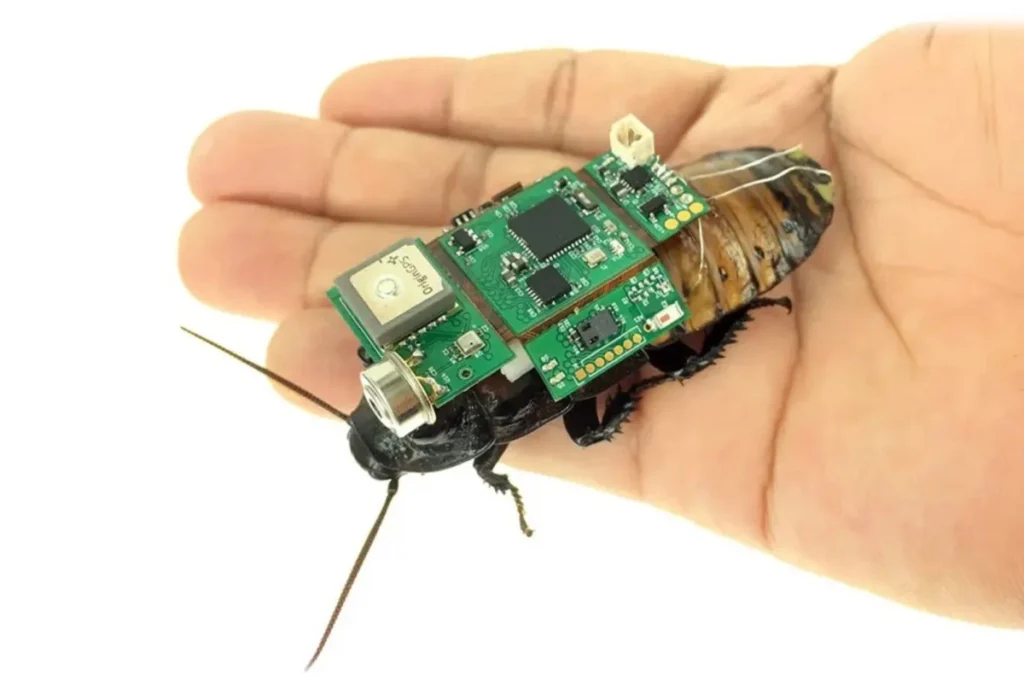

A robot equipped with computer vision then identified the body structures of each cockroach, accounting for individual size differences, and determined the precise implantation site. Using a robotic arm, an electronic backpack was then implanted onto the insect, with mounting branches underneath the backpack to provide stability.

The results matched the performance of counterparts that had been manually assembled. Under a 0.4 second stimulation, the automatically assembled hybrid robots showed effective steering control of more than 70 degrees, and deceleration control of 68.2 per cent.

The team also tested a group of four hybrid robots outdoors on uneven terrain using an ultra-wideband localization system. Within 10 minutes, the robots had covered 80 per cent of a 4 square meter (43 square feet) obstacle-laden area. The scientists said their next challenge is to empower cyborg insects to operate autonomously, which could enable hundreds of such robots to be operated simultaneously.

“In the future, factories for insect-computer hybrid robots could be built to meet the demand for rapid preparation and deployment. Additional sensors could be integrated into the electronic backpacks to enable specialized applications, such as inspections and search missions,” the researcher said in their paper. The significant advance in the field of robotics could also have other potential applications spanning various industries and disaster response scenarios.