Kama JSC, which is engaged in development of the Russian Atom electric car, shared details about the One of the important design features of the future novelty. In particular, the manufacturer described in detail about how the unusual design of the swing doors of the car is arranged.

According to the Autopilot portal, first of all, such a decision made it possible to get rid of the central pillar of the body, which further increased the the volume of the interior space of the cabin. The doors themselves are equipped with electric drives, closers and sensors that work in conjunction with the driver assistance system (ADAS).

On the front door there is a retractable mechanical handle with a button, and for opening the doors from the car The keys built into the door panel respond. The electric actuators in this system are responsible for automatic opening and closing the tailgate, allowing the passenger to operate it alone Touch.

While China has been making all the technology running with its Electric Vehicles (EV) industry, the United States and European auto manufacturers have been left behind – mainly due to the US oil industry which has been slow to popularise non-oil fuel products. That tech gap has led the United States to place a 100% import tariff on Chinese EV’s.

But what about Russia’s EV industry?

Russia’s Izvestia newspaper (banned in the EU) has published an article about the production of a new Russian EV, “The Atom” and released a review of the vehicle. We have translated and tidied up their report as follows:

A new Russian electric car “Atom” will begin production in Moscow at the end of 2025. At present, it only exists in several prototypes, which are being used to improve the performance of the car.

At the Moscow Moskvich auto works, preparations for the serial production of the Atom EV are in full swing, according to Ivan Solomin, the Marketing Director. He told us that the first test machines are planned to be released at the end of this year (2024), including with full production, including welding and painting of the car body. The market serial production of the Atom is expected for Q3 2025. The Atom will retail for between ₽2.5 million to 3.5 million, (US$27,500 to US$40,000) depending on the model. That is comparable to a Tesla.

Last year, the Atom concept car, featuring some unusual technical solutions was first built. This included flaunted open doors and a steering wheel with a built-in touch LCD display. Solomin confirmed that these technical highlights will appear in serial production models.

The Atom’s software is being developed in Russia’s Kaspersky Laboratories and will allow the owner to remotely manage secondary machine systems via a mobile app downloaded to a smartphone.

Taxi Atom electric

This, combined with advanced telematics allow the user to quickly adapt the Atom for the needs of public hire and taxi companies. The taxi models will differ somewhat in layout from the public versions, in that there will be no front passenger seat — this space will be used to transport luggage.

This taxi model solution taxi is explained by the peculiarities of the car layout. The electric motor, developed jointly with Rosatom, is located in the rear of the car.

Atom electric Car Battery

The RA 77 kWh traction battery is equipped with a thermostat and is being developed jointly with Renner – the battery is being produced in Kaliningrad. It provides a power reserve of 500 km, with just eight minutes recharge needed to boost a further 100 km travel.

As security measures, built-in Sensors and cameras scan the surrounding area for danger, and when the system signals and blocks the doors from opening. The design of the car also implements a mechanism for stopping the door when an obstacle is detected when opening/closing, and an emergency possibility of manual opening of the door when there is no power.

It was decided early in the design process that the Atom would be rear-wheel drive. This made it possible to give the vehicle better maneuverability, due to the lack of drive shafts with hinges on the front axle, the steered wheels turn to a larger angle, providing the vehicle with a turn radius of just 4.9 m. In addition, as the engine is in the rear, the front of the car acts as a crash barrier in any frontal collision, providing the driver and front passenger with a higher level of safety.

To debug driving performance, 13 running prototypes, the so-called ‘mules’, were built. Their camouflaged bodies have nothing to do with the final model. The passenger cabin is also very basic from the production Atom model. Inside the mule prototypes are only the seats, the main controls and measuring instruments.

There are no ABS and ESP systems on the mules, as it is important for Moskvich to adjust the controllability of the machine in its purest form. Production vehicles will use ADAS 2.0+ electronic assistants.

The rear actuator, multiplied by a 204-strong electric motor, provides fast acceleration to 100 kmph in 8 seconds.

According to Statista, the Electric Vehicles market in Russia is projected to reach a revenue of US$46.5 million in 2024. The market is expected to experience an annual growth rate (CAGR 2024-2028) of 17.68%, resulting in a projected market volume of US$89.2m by 2028.

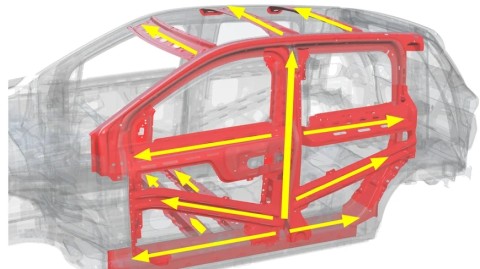

Due to the lack of a central Door lock racks are built into the thresholds, and their leaves are additionally close with each other. To increase the strength of the body, the manufacturer used stiffeners made of hot steel Stamping. In the company They explained that the main burden in such situations is taken on massive thresholds, in which the reinforced body of the traction battery is integrated.

Start of serial production Atoma is scheduled for the third quarter of 2025 at the Moskvich plant.